Lubrication Systems for Coil & Strip Stock

Do I need a lubrication system for coil and strip stock?

Graymills Stocklube® Systems provide neat, controlled industrial lubrication systems for coil and strip stock. They save time, save lubricant, extend die life and prevent slippery floor hazards. Stocklube® systems eliminate inefficient hand-brushing and messy containers. Ruggedly constructed to complement press speeds up to 300 FPM.

STOCKLUBE SYSTEM FEATURES

What are the key features of a Stocklube Lubrication System

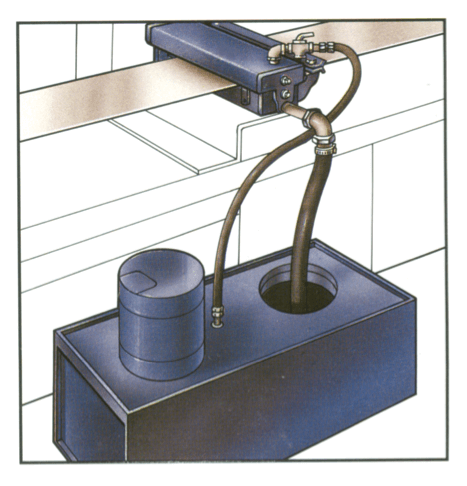

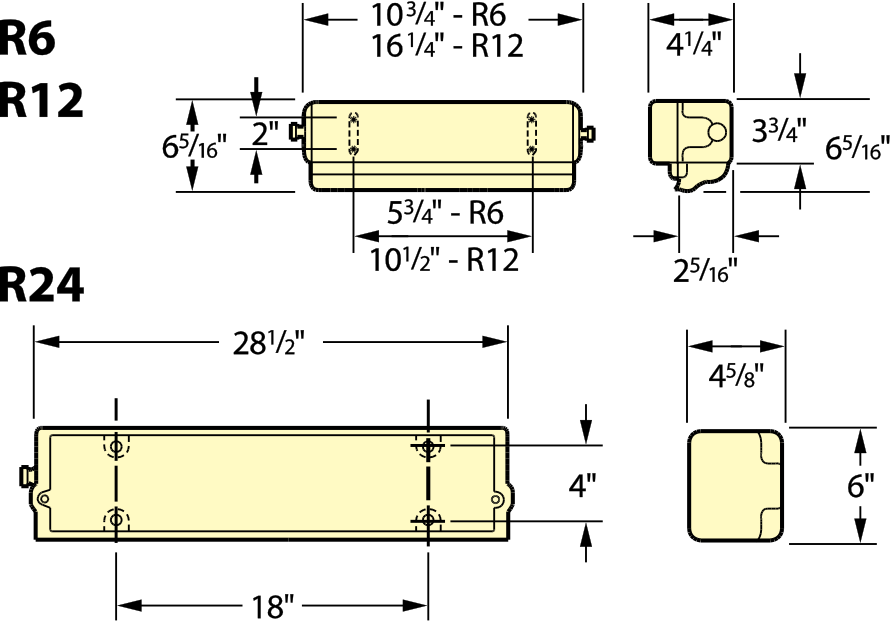

The systems consist of a lubricating head assembly and a pump and tank unit. Lubricating heads are available in three sizes for maximum sheet width of 6", 12" and 24" and are adjustable for stock thickness up to 3/16".

How does a stucklube Lubrication System Reduce die wear?

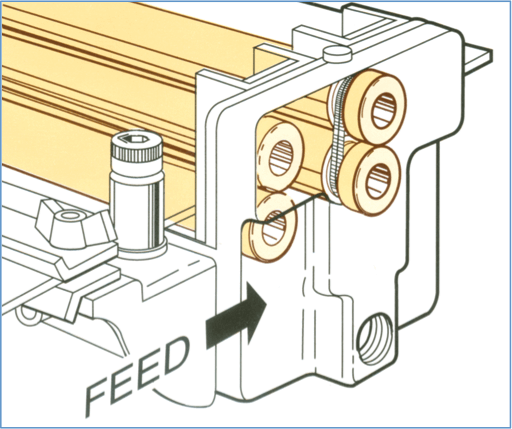

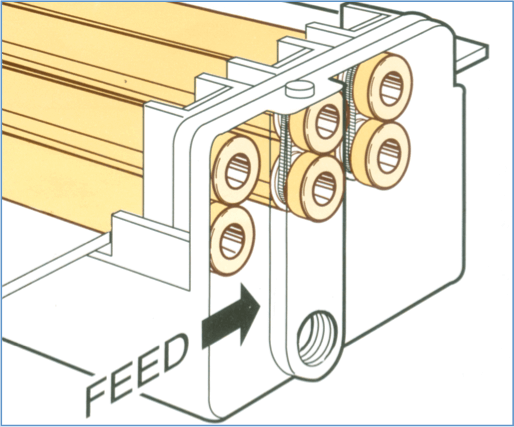

The stock is coated with lubricant as it passes through application rollers operating under spring tension. Excess lubricant is squeezed off by the wiper rollers and drains to the pump reservoir where it is filtered and recirculated to the head. Stocklube heads are easily adjusted to lubricate stock up to 3/16", either top, bottom or both sides simultaneously.

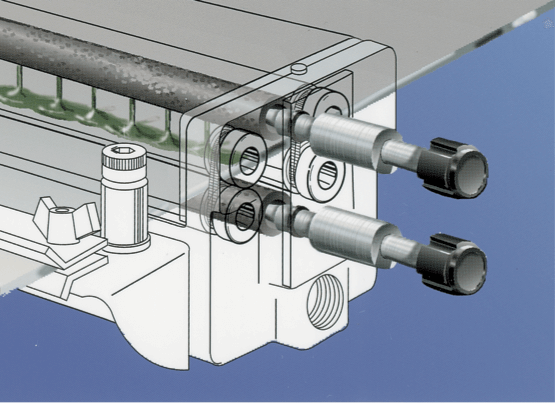

Uniform lubricant flow is easily adjusted with convenient manifold needle valves. In addition, the wiper rollers tend to clean dirt from the stock surface to keep foreign material from damaging dies. Dual manifold needle valves provide fingertip adjustment of the lubricant flowing on to the stock. This control allows operation at various production speeds.

What are the rollers in the Stocklube made from?

Smooth steel rollers are standard with Graymills Stocklube Systems.

Does the Graymills Stocklube System offer a choice of centrifugal or gear pump systems?

Centrifugal pump systems are for use with light oils and water-soluble mixtures up to 500 SSU. They will handle fluids containing abrasives or scale. For complete information, see FM60 Series centrifugal pumps.

Gear pump systems are for use with heavier lubricants (up to 5000 SSU) which are free of abrasives or scale. For complete pump information, see SG2 and SG4 Series gear pumps.

Stocklube units are easily installed in a variety of positions on all types of presses. The preferred position is between the roll feed mechanism and the fabricating equipment.

Dual manifold needle valves provide fingertip adjustment of the lubrication Flowing on to the stock. This control allows operation at various production speeds.

Independent manifold valves permit application of lubricant to either top, bottom or both sides simultaneously. There is no waste with a Graymills Stocklube System because unused lubricant is recirculated.

Six-inch and twelve-inch models have two sets of rollers. These units also have inlet roller guides adjustable for stock widths as narrow as one-inch to facilitate the feeding of sheet stock.

Twenty-four inch models have three sets of rollers to assure even distribution of the lubricant on larger sheet widths.

|

Combine these for a complete |

|||||||

|

Maximum Stock Width |

Head Only Model No. |

Pump and Tank Model No. |

Motor Hp |

Voltage |

Maximum Viscosity |

Tank Capacity Gallons |

Type of Pump |

|

6” |

R6 – STEEL OR R6U – URETHANE |

6FM68H |

1/8 |

A, B, F |

500 |

6 |

CENTRIFUGAL |

|

6SG2 |

1/8 |

A, B, F |

500 |

6 |

GEAR |

||

|

11SG4 |

1/4 |

E, F |

500 |

10 |

GEAR |

||

|

11SG4 |

1/2 |

E, F |

500 |

10 |

GEAR |

||

|

12” |

R12 – STEEL OR R12U – URETHANE |

6FM68H |

1/8 |

A, B, F |

500 |

6 |

CENTRIFUGAL |

|

11FM68H |

1/8 |

A, B, F |

500 |

10 |

CENTRIFUGAL |

||

|

6SG2 |

1/8 |

A, B, F |

500 |

6 |

GEAR |

||

|

11SG4 |

1/4 |

E, F |

500 |

10 |

GEAR |

||

|

11SG4 |

1/2 |

E, F |

500 |

10 |

GEAR |

||

|

24” |

R24 – STEEL OR R24U – URETHANE |

11FM68H |

1/8 |

A, B, F |

500 |

10 |

CENTRIFUGAL |

|

11SG4 |

1/4 |

E, F |

500 |

10 |

GEAR |

||

|

11SG4 |

1/2 |

E, F |

500 |

10 |

GEAR |

||

|

VOLTAGE SUFFIX CHART |

||||||

|

Suffix |

A |

B |

E |

F |

Z |

GAM(C) |

|

Voltage |

115 |

230 |

115/230 |

230/460 |

575 |

AIR |

|

Hertz |

50/60 |

50/60 |

50/60 |

50/60 |

50/60 |

AIR |

|

Phase |

1 |

1 |

1 |

3 |

3 |

AIR |