Double Diaphragm Ink Pumps

For applications requiring controlled flow rates from a trickle to 40 gallons per minute. Especially suited to the requirements of bottom printing corrugated lines, where a single pump provides both supply and suction return.

These pumps operate by the movement of two flexible diaphragms which move back and forth, alternately filling and emptying two chambers. Flow is controlled with the air inlet valve, which then determines pump speed. A variety of applications are possible because the pump’s inlets and outlets can be configured in different ways, such as “one-in one-out”, “1-to-1”, "two-in two-out”, or “2-to-2”. In the 1–to-1 option, one color is sent to the deck. In the “ 2-to-2” configuration, you can deliver one material and also draw it back, or deliver two inks to two different decks. Diaphragm pumps do have a pulsating flow and are best use with a Graymills surge suppressor/filter.

Double Diaphragm Series

ADVANTAGES to the Double Diaphragm Series:

- High pressure, air-driven diaphragm pump, ideal for fluid transfer

- Corrosion-resistant

- Self-priming with a dry lift capability ranging from 10' to 18' and a maximum flow rate of 40 GPM

- Self-cleaning

- Portable

- Diaphragms do have a pulsating flow and are best used with a Graymills surge suppressor/filter

- The unique "slide-valve" design prevents stalling even when running at the lowest speeds

- Pumps are designed for easy maintenance with a minimum number of parts. The air valve assembly is externally serviceable (no need to dismantle pump)

- Eight models to provide progressively higher flow rates and head pressures

- Can be combined with tanks to provide a complete, ready-to-install pumping system

Specifications

|

MODEL |

1/4” |

3/8" |

1/2” |

1” |

|

Pump Body |

Polypropylene |

Polypropylene |

Polypropylene Or Acetal (ATEX) |

Polypropylene Or Aluminum |

|

Diaphragms |

Teflon® |

Teflon® Or Hytrel |

Teflon® Or Hytrel |

Teflon® Or Hytrel |

|

Ball Check Valves |

Polypropylene |

Teflon® Or Hytrel |

Teflon® Or Hytrel |

Teflon® Or Hytrel |

|

Dry lift capability |

10 Feet |

12 Feet |

15 Feet |

18 Feet |

|

Total Developed Head |

150 Feet |

231 Feet |

150 Feet |

150 Feet |

|

Maximum Flow |

5 GPM |

7 GPM |

15 GPM |

50 GPM |

|

Air Inlet (NPT-F) |

1/4” |

3/8" |

1/4” |

1/2” |

|

Maximum Inlet Pressure |

100 PSI |

100 PSI |

100 PSI |

100 PSI |

|

Maximum Viscocity |

500 CPS |

1,000 CPS |

5,000 CPS |

10,000 CPS |

AIR-OPERATED DOUBLE DIAPHRAGM TRANSFER PUMP MODEL DPTG-50-DRUM

- Features 1-in/1-out 1/2" pump with Teflon® diaphragms and bottom suction manifold

- Quick priming and immediate flow. Runs dry without damage

- Handles fluid viscosities up to 5,000 CPS and solids up to 0.09 inches

- Pump slides in and out of drums through bung adapter without the need to disconnect hoses

- Pump is never immersed inside the drum

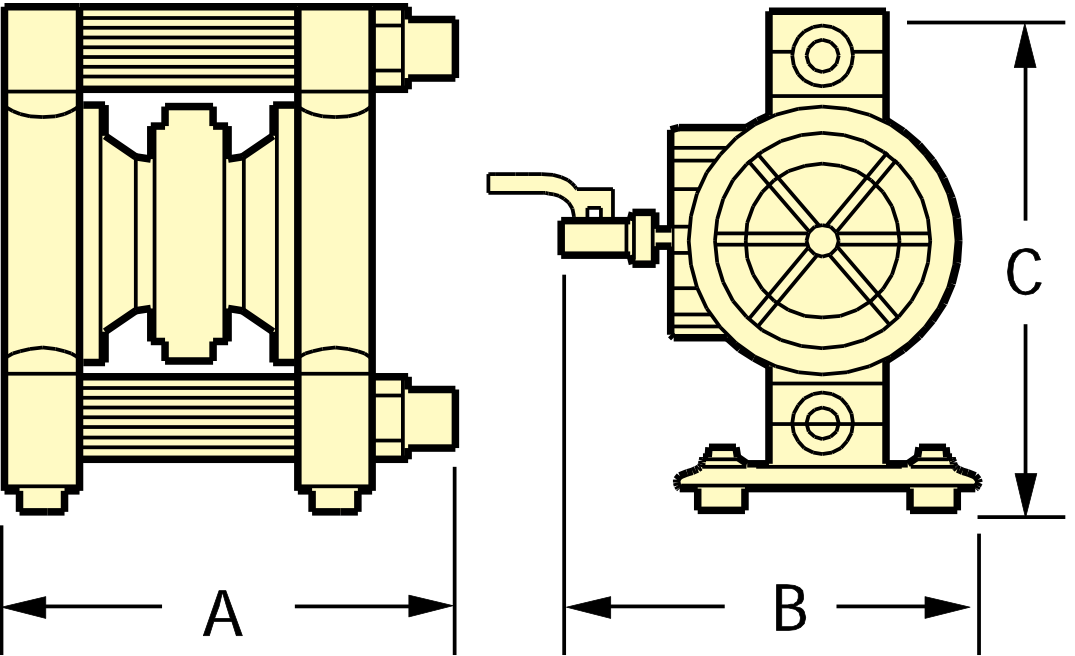

Dimensions And Order Information

|

DOUBLE DIAPHRAGM SERIES DIMENSIONS |

|||

|

Model |

A |

B |

C |

|

1/4” |

6-7/32” |

6-1/2” |

5-13/16” |

|

1/2” |

8-7/8” |

9-5/32” |

11-3/4” |

|

1” |

13-7/32” |

13-3/8” |

17” |

|

DOUBLE DIAPHRAGM SERIES MODELS |

|||

|

Pump |

Diaphragms |

Ball Checks |

Inlet / Outlet Configuration |

|

1/4” Models |

|||

|

DDPLTG-25 |

Teflon® |

Polypropylene |

1 in / 1 out |

|

3/8” Models |

|||

| DDPLHG-38 | Hytrel | Hytrel | 1 in / 1 out |

| DDPLTG-38 | Teflon® | Teflon® | 1 in / 1 out |

| DDPLHG-38-2 | Hytrel | Hytrel | 2 in / 2 out |

| DDPLTG-38-2 | Teflon® | Teflon® | 2 in / 2 out |

|

1/2” Models |

|||

|

DDPLHG-50 |

Hytrel |

Hytrel |

1 in / 1 out |

|

DDPLTG-50 |

Teflon® |

Teflon® |

1 in / 1 out |

|

DDPLHG-50-2 |

Hytrel |

Hytrel |

2 in / 2 out |

|

DDPLTG-50-2 |

Teflon® |

Teflon® |

2 in / 2 out |

|

DACT-50 |

Acetal |

Acetal |

1 in / 1 out |

|

DDPLTG-50-DRUM |

Teflon® |

Teflon® |

1 in / 1 out |

|

1” Models – Aluminum |

|||

|

DDALHGR-100 |

Hytrel |

Hytrel |

1 in / 1 out |

|

DDALHGR-100 |

Teflon® |

Teflon® |

1 in / 1 out |

|

1/2" DIAPHRAGM PUMPS WITH DUCK BILLS |

|||

| DDPLQHG-50 | Hytrel | Buna (DB) | 1 in / 1 out |

|

DDPLQTG-50 |

Teflon® |

Buna (DB) |

1 in / 1 out |

|

DDPLQHG-50-2 |

Hytrel |

Buna (DB) |

2 in / 2 out |

Valve Kit Story

Ours

Theirs

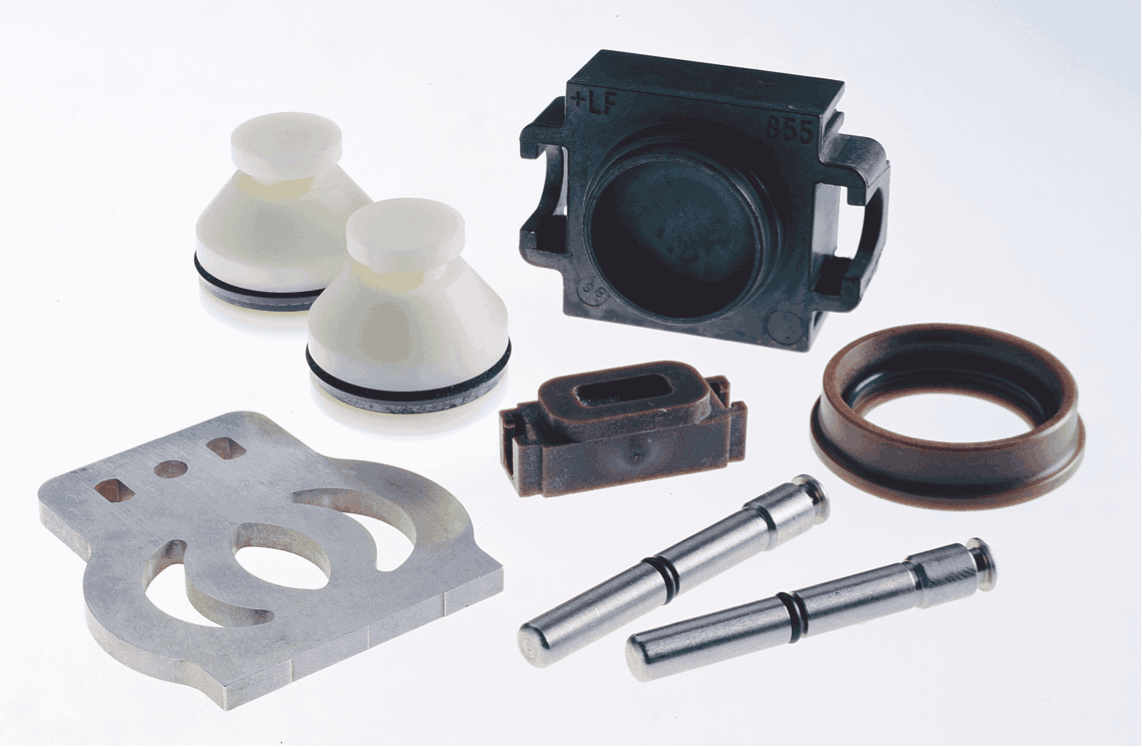

Quick-Change Air Valve Service Kits Have Over 50% Fewer Parts than Competitors... and the Pump is Externally Serviceable

Graymills diaphragm pumps feature air valve service kits that are 100% externally serviceable and contain a maximum of 10 parts. Competitor service kits have 20 to 30 parts that need to be replaced and their pumps must be completely disassembled to service the air valve. Look at these remarkable differences:

- Extremely reliable—resists stalling

- Fewer parts—repair kits have up to 50% fewer parts than traditional valve kits

- Ease of repair—the air valve can be repaired externally. The pump itself never has to be disassembled. Repairs are so easy they can take place where the pump is installed, which saves time, money and frustration.

- Unique U-cup seals—last longer and are more reliable than o-ring seals

- Less prone to icing—no small passages where ice can build

- No lubrication required—pump performance will not be adversely affected by "dirty" or unconditioned air.